AISI/SAE 4140 Carbon Steel Bar

Classification :

PRODUCT DETAILS

AISI/SAE 4140 Carbon Steel Bar Description

4140 is a 1% chromium-molybdenum medium hardenability general-purpose high-strength steel, usually hardened and tempered in the tensile range of 850-1000 Mpa (condition T). 4140 now have improved machinability, which greatly increases feed and/or speed, while extending tool life without affecting mechanical properties. The prehardening and tempering 4140 can be further case hardened by flame or induction hardening and nitriding.

Product Parameters

|

Product Name |

AISI/SAE 4140 Carbon Steel Bar | |||

|

Standard |

EN/DIN/JIS/ASTM/BS/ASME/AISI, etc. |

|||

|

Common Round Bar Specifications |

3.0-50.8 mm, Over 50.8-300mm |

|||

|

Flat Steel Common Specifications |

6.35x12.7mm, 6.35x25.4mm, 12.7x25.4mm |

|||

|

Hexagon Bar Common Specifications |

AF5.8mm-17mm |

|||

|

Square Bar Common Specifications |

AF2mm-14mm, AF6.35mm, 9.5mm, 12.7mm, 15.98mm, 19.0mm, 25.4mm |

|||

|

Length |

1-6meters, Size Accept Custom |

|||

|

Diameter(mm) |

Hot Rolling Round Bar |

25-600 |

Cold Rolling Square Bar |

6-50.8 |

|

Hot Rolling Square Bar |

21-54 |

Cold Rolling Hexagon Bar |

9.5-65 |

|

|

Cold Rolling Round bar |

6-101.6 |

Forged Rebar |

200-1000 |

|

|

Surface Process |

Bright, Polished, Black |

|||

|

Other Services |

Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. |

|||

Chemical Composition

|

Grade |

Mn |

S |

C |

P |

Si |

Cr |

Ni |

|

AISI 4140 |

0.75-1.00 |

0.035 |

0.38-0.43 |

0.035 |

0.20-0.35 |

0.8-1.1 |

0.15-0.25 |

Mechanical Properties

|

Grade |

Tensile Strength psi |

Yield Strength psi |

Elongation % |

Hardness HRC |

|

AISI 4140 |

100k |

80k |

20 |

18-22 |

Scope of Application

SAE 4140 are widely used in most industrial sectors, with a wide range of applications, such as: adapters, spindles, axles, bolts, crankshafts, connecting rods, chuck bodies, chucks, conveyor belt pins and rollers, ejection pins, forks, gears, Guide rods, hydraulic shafts and parts, lathe spindles, logging parts, milling spindles, motor shafts, nuts, clamping rods, various pins, pins, pump shafts, plungers, sleeve, spindle, sprocket, stud bolt, tool holder, torsion bar, worm, etc.

| USA | Japan | Germany | U.K. |

|

France | Italy | Spain | Switzerland | China | |

|

AISI/SAE |

JIS |

W‐nr. |

DIN |

BS |

EN |

AFNOR |

UNI |

UNE |

SS |

GB |

|

A570.36 |

STKM 12A |

1.0038 |

RSt.37‐2 |

4360 |

‐ |

E 24‐2 |

‐ |

‐ |

1311 |

15 |

|

- |

STKM 12C |

- |

- |

40 C |

- |

Ne |

- |

- |

- |

- |

|

1015 |

‐ |

1.0401 |

C15 |

080M15 |

‐ |

CC12 |

C15, C16 |

F.111 |

1350 |

15 |

|

1020 |

‐ |

1.0402 |

C22 |

050A20 |

2C |

CC20 |

C20, C21 |

F.112 |

1450 |

20 |

|

1213 |

SUM22 |

1.0715 |

9SMn28 |

230M07 |

1A |

S250 |

CF9SMn28 |

F.2111 |

1912 |

Y15 |

|

11SMn28 |

||||||||||

|

12L13 |

SUM22L |

1.0718 |

9SMnPb28 |

‐ |

‐ |

S250Pb |

CF9SMnPb28 |

11SMnPb28 |

1914 |

‐ |

|

‐ |

‐ |

1.0722 |

10SPb20 |

‐ |

‐ |

10PbF2 |

CF10Pb20 |

10SPb20 |

‐ |

‐ |

|

1215 |

‐ |

1.0736 |

9SMn36 |

240M07 |

1B |

S300 |

CF9SMn36 |

12SMn35 |

‐ |

Y13 |

|

12L14 |

‐ |

1.0737 |

9SMnPb36 |

‐ |

‐ |

S300PB |

CF9SMnPb36 |

12SMnP35 |

1926 |

‐ |

|

1015 |

S15C |

1.1141 |

Ck15 |

080M15 |

32C |

XC12 |

C16 |

C15K |

1370 |

15 |

|

1025 |

S25C |

1.1158 |

Ck25 |

‐ |

‐ |

‐ |

‐ |

‐ |

‐ |

25 |

|

A572-60 |

‐ |

1.890 |

StE380 |

4360 55 |

‐ |

‐ |

FeE390KG |

‐ |

2145 |

‐ |

|

1035 |

‐ |

1.0501 |

C35 |

060A35 |

‐ |

CC35 |

C35 |

F.113 |

1550 |

35 |

|

1045 |

‐ |

1.0503 |

C45 |

080M46 |

‐ |

CC45 |

C45 |

F.114 |

1650 |

45 |

|

1140 |

‐ |

1.0726 |

35S20 |

212M36 |

8M |

35MF4 |

‐ |

F210G |

1957 |

‐ |

|

1039 |

‐ |

1.1157 |

40Mn4 |

150M36 |

15 |

35M5 |

‐ |

‐ |

‐ |

40Mn |

|

1335 |

SMn438(H) |

1.1167 |

36Mn5 |

‐ |

‐ |

40M5 |

‐ |

36Mn5 |

2120 |

35Mn2 |

|

1330 |

SCMn1 |

1.1170 |

28Mn6 |

150M28 |

14A |

20M5 |

C28Mn |

‐ |

‐ |

30Mn |

|

1035 |

S35C |

1.1183 |

Cf35 |

060A35 |

‐ |

XC38TS |

C36 |

‐ |

1572 |

35Mn |

|

1045 |

S45C |

1.1191 |

Ck45 |

080M46 |

‐ |

XC42 |

C45 |

C45K |

1672 |

Ck45 |

|

1050 |

S50C |

1.1213 |

Cf53 |

060A52 |

‐ |

XC48TS |

C53 |

‐ |

1674 |

50 |

|

1055 |

‐ |

1.0535 |

C55 |

070M55 |

9 |

‐ |

C55 |

‐ |

1655 |

55 |

|

1060 |

‐ |

1.0601 |

C60 |

080A62 |

43D |

CC55 |

C60 |

‐ |

‐ |

60 |

|

1055 |

S55C |

1.1203 |

Ck55 |

070M55 |

‐ |

XC55 |

C50 |

C55K |

‐ |

55 |

|

1060 |

S58C |

1.1221 |

Ck60 |

080A62 |

43D |

XC60 |

C60 |

‐ |

1678 |

60Mn |

|

1095 |

‐ |

1.1274 |

Ck101 |

060A96 |

‐ |

XC100 |

‐ |

F.5117 |

1870 |

‐ |

|

W1 |

SK3 |

1.1545 |

C105W1 |

BW1A |

‐ |

Y105 |

C36KU |

F.5118 |

1880 |

‐ |

|

W210 |

SUP4 |

1.1545 |

C105W1 |

BW2 |

‐ |

Y120 |

C120KU |

F.515 |

2900 |

‐ |

Packing and delivery

The products have been exported to more than 100 countries and regions, including Turkey, Russia, Saudi Arabia, UAE, Iran, Kuwait, Poland, Philippines, Indonesia, Kazakhstan, Brazil, Mexico, Egypt, Nigeria, South Africa, Australia, etc.

CUSTOMER VISIT

All the products we offer strictly comply with international standards. Common specifications or grades of products are fully stocked, if you require a quote or more details on a specific product, please feel free to contact us.

Customer photo

Customer photo

Customer photo

Customer photo

Customer photo

Customer photo

FACTORY WORKSHOP

The company stocks The quantity is sufficient and the varieties and specifications are complete. The factory has introduced advanced production equipment and testing equipment such as oil mill wire drawing machines, sintering machines, pelletizing machines, and shearing machines.

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

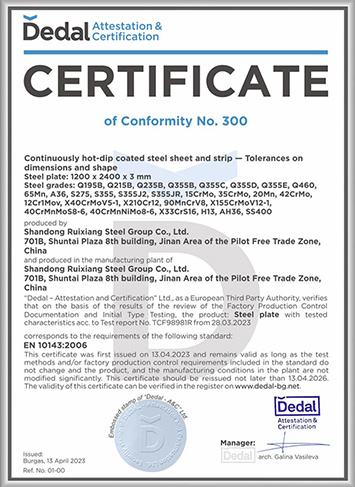

CERTIFICATE OF HONOR

COOPERATIVE PARTNER

APPLICATION AREAS

Ship

Chemical Industry

Electricity

Oil and gas transportation

FAQ

Once the products received by customer were found not comply with the products or contract demands, what will you do?

Do you provide samples Is it free or extra?

What certifications do your products have?

What kind of payment terms would you accept?

What is the delivery time?

What is your MOQ?

RELATED PRODUCTS

GET A FREE QUOTE